How Kuraray Leveraged RFID to Transform Returnable Asset Tracking

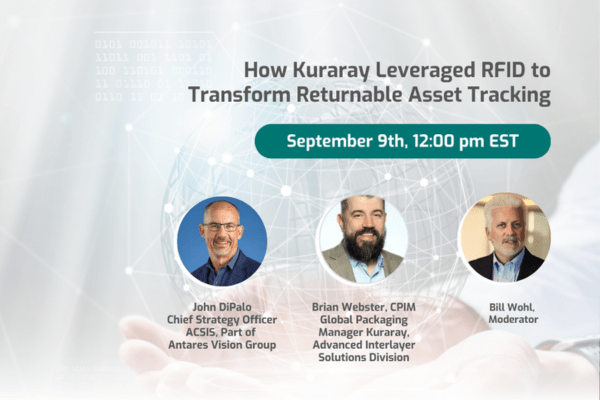

A LinkedIn Live Recap Featuring Brian Webster at Kuraray America and John DiPalo at ACSIS

Hosted by Bill Wohl on September 10, 2025

Watch the Full LinkedIn Live Recording

If you missed our recent live session on LinkedIn, no worries. You can catch the full replay right here:

🎧 Listen to the full podcast here

📄 Transcript included below

Key Takeaways from the Discussion

This session tackled a hidden cost in many supply chains: returnable shipping assets. Whether you’re sending steel crates, cable reels, or pharma totes, managing these assets the right way can mean the difference between excess costs and efficient operations.

Here’s what we learned:

Returnable Assets Are Big, Heavy, and Expensive

Kuraray ships massive steel pallets and crates — some weighing thousands of pounds and worth thousands of dollars each. Losing track of them isn’t just frustrating — it’s costly.

Visibility Begins at the Warehouse

Before implementing RFID tracking, Kuraray lost sight of its returnable containers once they left the dock. Now, thanks to overhead RFID readers and SAP integration, they know exactly when a container leaves and returns — and how long it sits at customer sites.

Smarter Fleet Management = Less Waste

Before tracking, Kuraray estimated its asset pool size manually. Now, with real data from AssetTrack, the team is tightening inventory and making smarter purchasing decisions — with fewer emergency buys and better maintenance tracking.

RFID Over GPS? Here’s Why

RFID was the better fit due to its reliability, cost-efficiency, and ease of integration — even with steel containers, which typically interfere with basic tags. GPS was ruled out due to the need for batteries and charging infrastructure.

The Dashboard Tells All

The new dashboard doesn’t just show where assets are. It helps drive real conversations about asset lifespan, turnaround times, and smarter usage strategies.

🎙️ LinkedIn Live Transcript: How Kuraray Leveraged RFID to Transform Returnable Asset Tracking

Below is the full transcript from the LinkedIn Live session, lightly edited for clarity and formatting.

Bill Wohl: Hello and welcome to today’s LinkedIn live program as we explore supply chain best practices and today in returnable asset tracking, talking about how to keep track of those specialized shipping assets and getting more out of your supply chain, brought as always to you by my friends at the Antares Vision Group, the real experts in supply chain and technology.

Hello everyone, again I’m your host Bill Wohl, and I’ve worked in the enterprise software and data space for more than 20 years, ever fascinated by the intersection of business and technology. No matter what industry you work in, managing materials and the carriers that transport materials is mission-critical for supply chain managers. I’ve been fortunate to cover the latest in technology developments to address these critical issues out at the edge and into the core ERP solutions, and it continues to amaze me how best practices in supply chain can be addressed across industries.

Today, we’re going to dig into proven strategies to optimize returnable asset inventory and track those items along the supply chain, and get the real benefit of having a customer with us today who is doing so right here on our program. Now our conversation is an interactive one so welcome to everyone who’s joining. I encourage you in the audience to participate. Use our webinar platform to do a couple of things: give us your name, title, and where you’re located so we get a sense of the audience, and we can adapt the program to that. You can use that same comments area to throw out a question for our visiting customer and our supply chain expert, and we’ll try to address them during the course of our time together.

My most productive conversations have been with my friends at ACSIS, now a part of the Antares Vision Group. So it’s my pleasure to welcome a regular guest of mine, Chief Strategy Officer John DiPalo, to the program. John, good to have you along.

John DiPalo: Bill, it’s good to be talking with you once again. I’m excited about this subject today.

Click to expand full transcript

Bill Wohl: It’s even better because people are tired of hearing just you and I talk, so we’re really lucky to have a customer — a special guest — the global packaging manager for Kuraray America’s advanced interlayer solutions division, Brian Webster. Brian, great to have you with us today.

Brian Webster: Great to be here, Bill.

Bill Wohl: Always excited to have a customer’s perspective. So, before we jump into the program, let’s just talk a little bit first about Kuraray. That was a company I had to learn about — it’s not a common name. What is the business, and what are the products we’re talking about?

Brian Webster: So Kuraray is a global company headquartered in Japan. We do a whole bunch of things. We’re in just about everything, but the division I work for — the AIS division — we make inner layers. We make glass inner layers for the architectural and automotive industries.

Bill Wohl: So if we think about that — if I take just my naive, don’t-know-too-much-about-it perspective — these are the materials or films, if you will, between layers of glass that provide stability and strength. What do these pieces of film do?

Brian Webster: That’s correct. Also acoustic. Basically, it’s the inner layer that we extrude that gets laminated by our customers between two pieces of glass that keeps it from breaking into a million pieces.

Bill Wohl: Okay, very cool. Always something different on this program.

John, let’s start with the basics. At its core, the discussion really is about how to manage returnable assets. When you think about that as a business challenge, talking to customers like Brian, what are the aspects of returnable assets that we tend to focus on?

John DiPalo: Yeah, so as we move to a more circular economy, what we’re starting to see are more and more companies wanting to ship either product or assets or other items in containers that can be reused. These are items that go out, and then the containers come back. The reason for that is that there are multiple reasons. You get better protection for the product, you can reuse these containers multiple times across their lifespan, and environmentally it’s more friendly. So there’s a bunch of reasons for utilizing returnable assets within your supply chain.

The challenge is that oftentimes what we see across our customer base is either the inability to get them back in a timely manner, or damage—when they’re out in the field and come back, the returnable asset is damaged or needs to be repaired, or it’s not usable, or they get lost. Those are some of the initial challenges. Other challenges we see are around fleet management: once you have a fleet of returnable assets within your supply chain, you want to make sure they’re in the right place at the right time so that you can manufacture properly and ship on time. You don’t want too many, because that’s excess cost, and you don’t want too few, because that can stop production or force one-way shipments—both of which are costly and inefficient.

So those are the challenges we see, and the solutions we put in place are built to address all of those and help maximize the use of your returnable fleet.

Bill Wohl: So Brian, John and I, have had a number of these conversations about returnable assets, and it’s been kind of fascinating because some of these carriers can be very expensive and highly complex. We did a session recently about very large wooden reels used for transporting cable—just the cost and weight of those reels and the time they sit in yards was fascinating.

You talked a little bit about interlayers. Are these materials in rolls or are they rigid and flat? What do the carriers for your business look like?

Brian Webster: Yeah, so we manufacture our interlayers in both roll form and sheet form. Some of the thicker materials have to go in sheet form because once you get to a certain caliper, you can’t roll it up. So if you think about a window in a skyscraper—imagine the size of the pallet that needs to go on. The rolls are a bit easier, but they’re still pretty big—pretty wide—and they’re made of steel. They have to be robust.

Bill Wohl: We’re always thrilled when we get a customer on a program, and there’s always this balance between sharing with the audience and maintaining your proprietary trade secrets. Can you give us a sense of what the weights of these shipping containers are, just so the audience can understand what you’re dealing with? And can you put a rough value on what a container is worth?

Brian Webster: Sure. High hundreds to a few thousand pounds for the big steel pallets I just mentioned. And cost-wise, high hundreds into the thousands as well.

Bill Wohl: So if you spread that out across the number of carriers you’re managing, that’s a significant number for the business. John mentioned the upsides and downsides of returnables versus one-way containers. Certainly at your manufacturers—where your materials are going—if they had to dispose of all these containers, that’s a cost in trash, space, and time. So the value for you is to avoid that for the customer and not have to rebuild these over and over again.

But anybody who’s not in your space would say, “Well, every building is different.” Do these packages wind up being customized for each client, or are you able to standardize on certain types of carriers for rolled or flat material?

Brian Webster: Yeah, so we have about five or six solutions—I believe it’s five at this point—for the crates, and one more in development. It’s pretty standardized right now. That could change, but that’s our current offering for returnables here in the U.S.

Bill Wohl: I know you’re well along on this project and really starting to get a sense of it. Take us back to where you were before. Were these assets largely manually tracked? Someone keeping a spreadsheet? What’s the before-and-after?

Brian Webster: Yeah, so we have had visibility in SAP once the assets come into our facility. They were—and hopefully that’ll change here within the next few weeks—entered manually into SAP. We see them flow through the manufacturing process, but once they go out the door to our customers, they just go into a black hole—or until recently, that is—until they came back and we wrote them back on.

Bill Wohl: If I understand your business, you’re sending your materials to another party who will ultimately get them to, in the example you gave, a window manufacturer who applies them downstream. Are you tracking every step of the way, or is your concern more about knowing when it leaves your dock and when it returns?

Brian Webster: We have great partnerships with our customers and work very closely with them—most of them are rather large customers. What’s important to us is when they go to that customer, how long they sit there—we get into dwell time and things of that nature. But really, what’s most important is where did they go and when did they come back.

Bill Wohl: John, in a previous program, I’ll go back to the cable reel example. We talked about tracking them all the way out to laydown yards where the material might sit before it’s used and then sit again before it’s returned. Are you seeing customers more like Brian—just wanting to know when it leaves and comes back—or are others tracking every step?

John DiPalo: I think it’s an evolving process, Bill. What we primarily see right now is a check-in/check-out process. I have an asset, it’s going somewhere. One of the things we do is determine transit time for the asset itself. We can do some carrier integration too, so we know where the asset is as it moves through the supply chain.

We have had customers who want to do more of what I call an electronic Kanban. They receive the asset and that triggers an event in the supplier’s system that says, “Okay, let me prepare a new shipment,” because they know it will be consumed. These follow-on activities give you more visibility with partners.

What I like to think about is using the returnable asset as a proxy for the product. So when it’s seen at various points in the supply chain, that visibility means something—it could trigger reorder points or help predict return timing. Those touchpoints give you much better control over the whole supply chain.

Bill Wohl: I’d guess that a lot of people listening today aren’t in the glass interlayer space. But we’ve had folks on this program who transport pharmaceuticals or food—highly regulated industries. We’ve talked about cable reels, car parts going back and forth in carriers for just-in-time inventory. So John, while not everyone is in Brian’s industry, what lessons apply broadly?

John DiPalo: Right—when you boil it down, one big one is fleet sizing. Returnables are typically more expensive than one-way packaging. So you want the right number—enough to meet demand, but not excess. That’s true in any industry.

Also, with returnables, your product tends to be much better protected. Quality of delivery improves. And with a properly designed returnable asset, you can pack it into a truck the same way every time. It’s consistent, protected, and just a better way to move product—once your network is in place.

Bill Wohl: Brian, I know listeners love the details. So let’s talk about tracking technology. We’ve discussed barcodes, GPS, RFID. Your packaging is unique. What did you choose and why?

Brian Webster: We explored a few options. We ended up going with RFID. GPS was an option, but GPS tags require batteries, which means recharging, and that’s a separate process to manage. Managing the fleet is already challenging. So while GPS tags were fancy with a lot of features, it didn’t make sense for us.

We worked with ACSIS, the expert in the field. RFID is tried and true. It’s not going anywhere. One challenge was that the assets are made of steel, which causes interference. So we couldn’t just stick on a basic RFID tag—you need something more robust.

We explored a few types of tags. The smallest one didn’t work. The next size up worked okay but not great. The one circled in red is the one we chose. There was another that Peter at ACSIS told us is used on army tanks—but we didn’t need to go that far.

With the tags we chose, we’re getting really good reads. It’s working well for us.

Bill Wohl: So you’re scanning those tags in the warehouse—at the loading dock—for departure and return. How are you doing the scan? Is it manual at the truck bay, or have you installed readers around the building?

Brian Webster: We went with overhead readers. We explored different options. One of our other sites uses RFID tracking with smaller readers on tripods at each side of the door. But we were excited to learn from ACSIS that overhead readers don’t take up space, and they’re more reliable for our needs.

We may have gone slightly overboard in terms of capability, but we wanted to err on the side of caution. And with these readers, we’re getting excellent read results.

Bill Wohl: You mentioned earlier that once the products go out the door, you had lost track of them—again, using my words. This is really about understanding when they leave and return. So what drove the decision to not read at customer sites or along the route? Why was just reading at your warehouse enough?

Brian Webster: That really came down to the SAP integration. During the design phase, we were asked if we wanted readers at our warehouse, the customers’ sites, etc. But with integration into SAP, we linked the batch to the asset as soon as the roll or sheet goes into the asset. Once linked, SAP already has the movements. So all we needed was a scan when the asset leaves and comes back.

We didn’t have to install readers at every customer location. That reduced complexity, cost, and coordination across a wide customer base.

Bill Wohl: John, when customers evaluate tracking technologies—RFID, GPS, barcodes—what are they thinking through in those early design conversations?

John DiPalo: We advise customers to take a multimodal approach. For example, even if you go with RFID, you can also have a barcode version of the same tag. That way, if someone doesn’t have RFID infrastructure, they can still scan with a mobile app or a simple handheld reader.

This makes it easier to bring customers into the process without requiring them to build infrastructure. With Brian’s case, they integrated the returnable asset and the batch in SAP. So now all that contextual data is available to stakeholders throughout the supply chain.

That visibility makes the system much more valuable—not just for tracking the container but for understanding where the product is, how it’s being used, and when it’s likely to return.

Bill Wohl: So downstream customers—like the skyscraper project in Brian’s example—don’t just have to trust that the product is on its way. The system can show it’s moving. That visibility, enabled by readers and tags, adds a deeper layer of value, right?

John DiPalo: Exactly. You’re building a high-fidelity view of the supply chain. The asset knows what’s been loaded into it, and every read provides another data point: how long it’s been out, where it is, if it’s in the wrong place, etc.

And as technology becomes more common at construction sites, for example, we’ll be able to detect that an asset entered a site, was consumed, and then returned. That’s the power of combining asset tagging, contextual data, and integration with ERP systems like SAP.

Bill Wohl: Let’s go deeper into the business case. Brian, any IT project has to justify its cost. For returnable assets, is the ROI mainly about using the same asset 3, 4, or 5 times until it pays for itself? Is that the basic equation?

Brian Webster: Pretty close. The returnable assets are expensive, but the single-use alternatives we replace them with are also expensive. So yes, after a few turns, the returnable asset pays for itself. But the real value of the system for us is in fleet sizing.

It’s tough to determine how many assets you need to support demand if you don’t know how many you actually have. We were estimating that, and to the team’s credit, we were doing okay. But now that we’re getting real data out of the system, we’re learning quickly and making better decisions.

Now, instead of asking, “Do we need 2,000 more of these?” we can ask, “Would 1,000 be enough if we manage the fleet better?”

Bill Wohl: So, without giving away proprietary data, do you feel your estimates were pretty accurate, now that you’re actually tracking things? Or are you finding out you could run leaner?

Brian Webster: We’re in a good place. It’s early, but AssetTrack is helping us tighten things up. This data has already triggered conversations we weren’t having before.

We used to buy new assets based on when we were running out, which isn’t ideal. But now, the team is happy with the investment, and we’re becoming more effective—not just in purchasing, but also in maintenance.

We found an asset from 1996 still in use. These can last 25–30 years, which is incredible. If we can manage them better, the long-term ROI is huge.

Bill Wohl: That reminds me of when I met a utility worker managing hundreds of thousands of telephone poles—on a spreadsheet. Tracking infrastructure like this is a game-changer.

How are you monitoring this day to day? Do you have a dashboard, and what KPIs matter most to you?

Brian Webster: Yes, we have a dashboard now. Until recently, everything was on spreadsheets. We’d take a snapshot, make assumptions, and go from there.

When we started tagging, we assumed we had about 3,500 assets. But our system showed only 2,500. That caused concern. On review, we realized our 3PL warehouse was tagging assets as they came back, but many assets weren’t yet in the loop.

That was on a Monday. By the following Monday, the warehouse had tagged another 5,000 assets. They acted quickly, and now we believe we’ll reach that 3,500 number, maybe more.

It also sparked a discussion: Are we managing assets first in, first out or based on proximity? That impacts wear and tear. So we’re making changes there, too—spreading out usage more evenly across the fleet.

Bill Wohl: For those tuning in, the dashboard Brian shared was helpful—and thank you for graying out sensitive data like customer names and locations. We always appreciate customers sharing real insight while protecting business details.

So Brian, as you look across your dashboard and processes, what are the most important KPIs driving your decisions?

Brian Webster: The big one is fleet sizing—making sure we have the right number of assets for our operational needs. Then it’s lead time, dwell time, number of assets in use, and even date of manufacture for each asset.

Before this system, if we wanted to know when an asset was manufactured, someone had to walk out and physically check it. Now, with the attribute tracking built into AssetTrack, we’ve got that info readily available. That’s a big improvement on the maintenance side.

Bill Wohl: You mentioned earlier that this rollout is U.S.-focused. But Kuraray is a global company. Is international expansion part of the roadmap?

Brian Webster: Definitely. We’ve already started rolling out a solution at our site in Trostberg, Germany. Progress is slow, but the need is clear.

In Ulsan, South Korea, space is more of an issue, but again, the need is there. Returnable assets make sense globally for both sustainability and cost-efficiency. RFID can work anywhere, and we’re exploring how ACSIS can support us across regions.

Bill Wohl: We always like to wrap these programs by discussing lessons learned. Brian, from a customer leadership perspective, what advice would you give to others considering a returnable asset tracking program?

Brian Webster: We touched on it earlier: tag selection is critical. Make sure you choose the right tags and technology upfront, and tailor it to your business needs before implementation.

We had great guidance from a colleague in Germany and support from the ACSIS team, particularly Peter, who helped with a clearly defined tagging process.

If you get that right early on, the rest of the implementation goes much smoother.

Bill Wohl: John, from your side, what are the key first steps for companies thinking about a returnable asset tracking initiative?

John DiPalo: Start by defining your end-state vision—what does success look like? Then build a technology roadmap to support it. You don’t need to turn everything on at once, but your infrastructure should allow you to scale.

In Brian’s case, we knew we needed an SAP-integrated solution that could track in and out movement. We iterated on a few designs before landing the final solution. But having the vision and aligning everyone around it made it work.

Don’t run a shortcut pilot that ends up being a dead end. Start with a functional solution that delivers value early, and build from there.

We had a strong team on both sides. Brian’s team was enthusiastic, and all stakeholders were involved—from operations to IT. That alignment and communication made a big difference. No major roadblocks.

The benefits and expectations were clearly communicated. That’s another key factor for a successful project.

Bill Wohl: We also got a great audience question around onboarding. For any IT project, user adoption is critical. Brian, can you share lessons on how you got people engaged and participating?

Brian Webster: Absolutely. As John mentioned, having the right players on the team matters. Our third-party warehouse, Onboard, was key. I’ve never seen two partners collaborate as closely as ACSIS and Onboard did here.

Buy-in was strong because we embedded the process into existing workflows. Assets came back, got remediated, and got tagged as part of the same process. Peter from ACSIS made sure everything was clearly documented. Everyone knew what to do and why it mattered.

We also worked with the Fayetteville operations team to make the process as seamless as possible. It’s still hard work—but if everyone understands the value, they’ll support it.

Bill Wohl: Couldn’t agree more. I’ve been in IT for over 30 years, and great partners plus strong communication are always the backbone of successful projects.

Brian, thank you for giving us such a transparent look into your project. It’s been extremely valuable for the audience to hear directly from a customer leading the effort.

Brian Webster: Thanks for having me. It’s been a great experience.

Bill Wohl: There’s a case study on this project, called AssetTrack, that goes into more detail—though anonymized to protect proprietary information. If you want a copy, just drop your name and email in the comments here on LinkedIn. If you’re watching the replay, we’ll continue to monitor and respond.

John DiPalo: Thank you, Bill. And Brian—thanks again for your insights.

Bill Wohl: Glad to have you both. For those attending PACK EXPO in Las Vegas on September 29, stop by the ACSIS / Antares Vision Group booth. John and the team will be there. Brian won’t be at that show, but some of the Kuraray team will be.

For more on supply chain and returnable asset solutions, follow John and the ACSIS team on LinkedIn. And check out the Diamind suite of solutions on their website. Thanks again to our guests and to the team at Antares Vision Group for bringing this program to life. I’m your host, Bill Wohl—thanks for joining us, and until next time, have a great day.

See You At Pack Expo

Some of the Kuraray and ACSIS teams will be on-site at PACK EXPO in Las Vegas on September 29. Stop by the Antares Vision Group booth and say hello!

Want to speak before then? Contact us today!